Aviation Maintenance Software is designed to streamline and optimize the management of aircraft maintenance, ensuring regulatory compliance, safety, and efficiency. These platforms help airlines, MRO (Maintenance, Repair, and Overhaul) providers, and private fleet operators manage inspections, work orders, and inventory while reducing downtime and costs.

Leading solutions in this category include TRAX Maintenance, Ramco Aviation Software, AMOS by Swiss-AS, WinAir, and Aircraft Maintenance Systems (AMS). These tools integrate with existing ERP and aviation management systems, supporting real-time data access and predictive maintenance strategies. Related categories include Fleet Management Software, Enterprise Asset Management (EAM) Software, and Manufacturing Execution Systems (MES).

TRAX Maintenance – A widely used solution for airlines and MRO providers, offering comprehensive work order and compliance management.

Ramco Aviation Software – A cloud-based platform that integrates predictive maintenance with supply chain and financial management.

AMOS by Swiss-AS – A powerful solution used by airlines and MROs for managing maintenance operations efficiently.

WinAir – Provides robust inventory and work order tracking for aviation maintenance teams.

Aircraft Maintenance Systems (AMS) – Offers detailed logbooks, compliance tracking, and task automation.

IFS Aviation Maintenance – Supports commercial and military aviation maintenance with strong ERP integration.

Rusada ENVISION – A scalable MRO software solution for various aircraft maintenance needs.

Ultramain M&E – Known for its mobile-first approach to aircraft maintenance management.

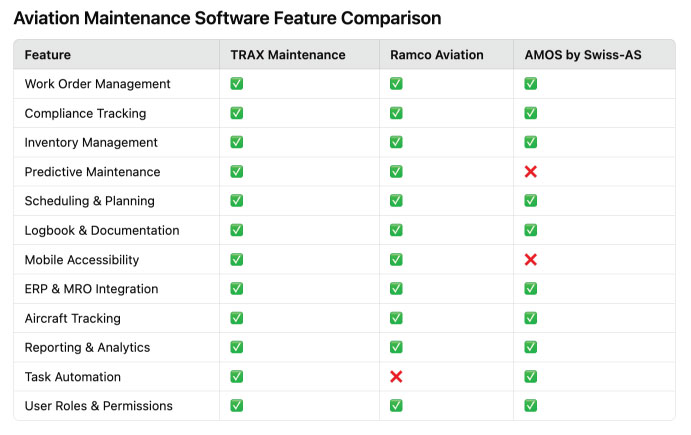

The table below compares three leading Aviation Maintenance Software solutions: TRAX Maintenance, Ramco Aviation Software, and AMOS by Swiss-AS. Each is evaluated based on its feature set, helping users identify the best fit for their needs.

The feature comparison table evaluates three leading Aviation Maintenance Software solutions—TRAX Maintenance, Ramco Aviation Software, and AMOS by Swiss-AS—based on 12 key features. All three platforms support essential functions like work order management, compliance tracking, and inventory management, ensuring regulatory adherence and efficient maintenance workflows. However, differences emerge in areas like predictive maintenance and mobile accessibility, where AMOS lacks predictive maintenance capabilities and TRAX and Ramco offer stronger mobile support. Additionally, Ramco lacks task automation, which TRAX and AMOS provide. This comparison helps organizations choose the right software based on their specific operational needs.

The video below provides a real-world example of how aviation maintenance software streamlines fleet management, regulatory compliance, and repair operations. As discussed on this page, these software solutions play a critical role in work order automation, compliance tracking, predictive maintenance, and inventory management.

This video showcases a modern Maintenance & Engineering (M&E), Maintenance, Repair & Overhaul (MRO), and Continuing Airworthiness Management Organization (CAMO) system, demonstrating how aviation professionals use digital tools to enhance efficiency and ensure aircraft safety. Watch to see how key features—such as aircraft tracking, logbook management, and real-time data analytics—help airlines and MRO providers maintain peak operational performance.

This example dashboard provides a comprehensive overview of aircraft maintenance operations, helping aviation professionals manage fleet upkeep with efficiency and precision. The interface displays aircraft status indicators, ensuring real-time visibility into each aircraft’s maintenance condition. Work order management tools allow technicians to track, update, and complete maintenance tasks seamlessly.

The dashboard also features compliance tracking, ensuring adherence to regulatory standards, and an inventory management section to monitor spare parts and tools. Predictive maintenance alerts use data analytics to detect potential issues before they lead to costly downtime. With a modern, data-driven layout, this dashboard reflects the core functionalities of industry-leading Aviation Maintenance Software solutions.

Aviation Maintenance Software incorporates critical functionalities to enhance aircraft safety, minimize operational disruptions, and improve overall efficiency. These tools help organizations track compliance, automate work orders, and maintain detailed records of all maintenance activities. By leveraging mobile access and predictive maintenance, aviation companies can prevent unexpected failures and keep fleets airworthy. Below is a detailed breakdown of the key features found in this software category.

Aviation maintenance software allows users to create, assign, and track work orders digitally, reducing paperwork and improving efficiency. Technicians can update job statuses in real time, ensuring that maintenance teams stay informed about task progress.

Regulatory compliance is crucial in aviation. These platforms help organizations track and document adherence to FAA, EASA, and other aviation regulatory bodies, ensuring that maintenance actions align with legal and safety requirements.

Effective inventory control prevents maintenance delays by ensuring that essential parts, tools, and consumables are available when needed. The software integrates with supply chain systems to manage stock levels and procurement.

By analyzing aircraft performance data, predictive maintenance tools identify potential issues before they cause failures. This reduces downtime and prevents costly unscheduled repairs.

Efficient scheduling minimizes aircraft downtime while ensuring routine maintenance is performed on time. This feature helps optimize workflows, balancing maintenance needs with operational requirements.

Aviation maintenance requires meticulous record-keeping. Digital logbooks store historical data on inspections, repairs, and part replacements, ensuring easy access for audits and regulatory checks.

Maintenance personnel can access crucial data, update records, and receive work assignments via mobile devices. This enhances efficiency, particularly for field operations.

Seamless integration with ERP (Enterprise Resource Planning) and MRO (Maintenance, Repair, and Overhaul) systems ensures synchronized financial, operational, and maintenance data.

Aircraft status, operational history, and upcoming maintenance requirements are tracked in real time, improving fleet visibility and decision-making.

Custom dashboards provide insights into maintenance performance, costs, and compliance. Automated reports assist in optimizing maintenance strategies and forecasting future needs.

Routine processes like scheduling, inventory reordering, and compliance alerts can be automated, reducing manual workload and enhancing efficiency.

Role-based access controls allow different levels of permissions for administrators, technicians, engineers, and auditors, ensuring data security and compliance.

Aviation Maintenance Software is a digital solution that helps airlines, MRO providers, and fleet operators manage aircraft maintenance, ensuring compliance and efficiency.

It is used by airlines, maintenance providers (MROs), aircraft manufacturers, and government aviation agencies to track and manage aircraft maintenance.

It ensures regulatory compliance by tracking inspections, documentation, and adherence to FAA, EASA, and other aviation standards.

Yes, most solutions integrate with ERP, MRO, and inventory management systems for seamless operations.

Predictive maintenance analyzes aircraft performance data to anticipate failures before they occur, reducing downtime.

It tracks spare parts, tools, and consumables, ensuring maintenance teams have what they need when they need it.

Yes, it automates work order creation, compliance tracking, and reporting to improve efficiency.

It monitors aircraft status, maintenance history, and upcoming service requirements to keep fleets operational.

The cost of Aviation Maintenance Software varies based on features, deployment type, and the number of aircraft managed. For example, WinAir offers tiered pricing starting at around $5,000 per year for small operators, while enterprise solutions like TRAX Maintenance can cost $50,000 or more annually, depending on customization and fleet size. Some vendors charge per aircraft or per user, and many offer custom pricing based on business needs.

Many Aviation Maintenance Software solutions integrate IoT (Internet of Things) sensors and real-time data analytics to enhance predictive maintenance and operational efficiency. IoT-enabled aircraft components continuously transmit performance data, such as engine temperature, hydraulic pressure, and vibration levels, to the software’s analytics engine. Advanced systems use machine learning algorithms to detect anomalies and predict potential failures before they occur. For example, Ramco Aviation Software leverages IoT-driven diagnostics to recommend proactive maintenance actions, reducing unplanned downtime. Additionally, edge computing in modern aircraft enables real-time data processing without waiting for cloud transmission, allowing immediate in-flight maintenance alerts.